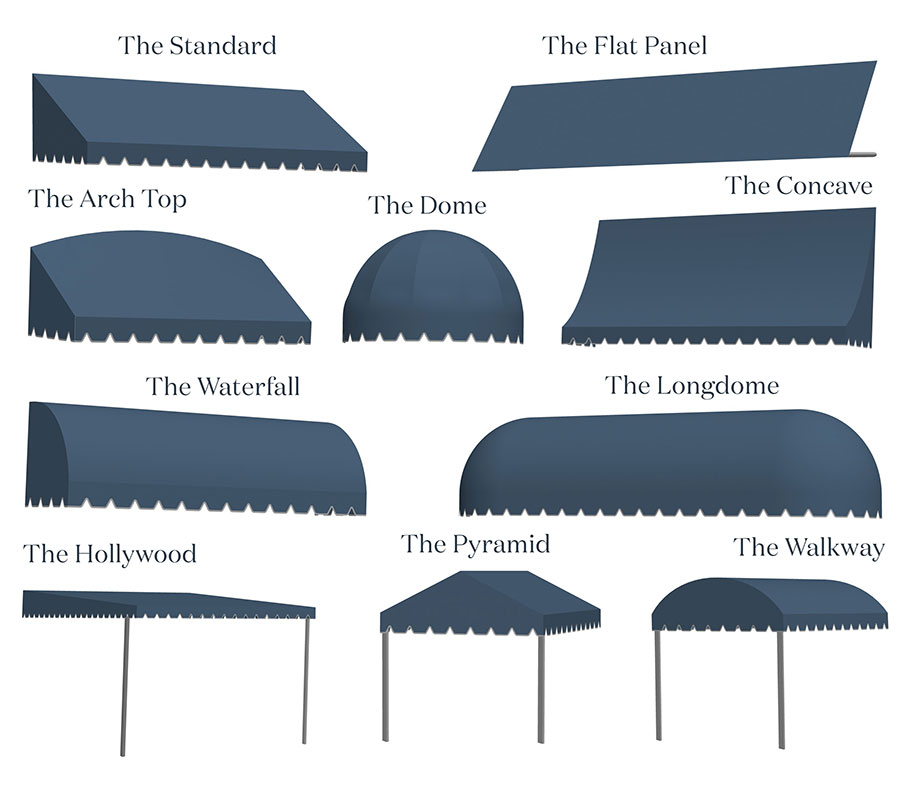

Shapes and Nomenclature

- Concave

- Dome

- Elongated dome

- Lateral arm/retractable

- Quarter round/convex

- Rounded entrance canopy

- Traditional

4 – Bar: This is the term commonly used to describe a stripe in awning fabric. This is the approximate number of colored 4 in. stripes across the width of 31 inch fabric. The stripes are not exactly 4 in., they are more like 3.8 in. Since many fabrics are wider than 31 in. today, this term is used to describe the width of the stripe. Also known as a classic stripe.

Abrasion resistance: Capacity of material to withstand wear due to friction, rubbing, or scraping.

Acceleration stress: Additional stress placed on rope due to increasing the velocity of load.

Acrylic: Generic term for manufactured fiber in which the fiber-forming substance is any long-chain synthetic polymer composed of at least 85% by weight of acrylonitrile units. Made in both filament and staple forms.

Adhesive/epoxy anchors: Attachment for installations onto masonry (including brick, marble, stone, stucco, etc.) or concrete. Ideal for use in anchoring to a variety of base materials ranging from soft common brick to hard marble or granite.

Aluminum pipe: Manufactured with the same dimensions as steel pipe, it weighs only one-third as much.

Aluminum tubing: This is available in a wide variety of shapes, sizes and tempers, with an array of advantages and disadvantages in comparison to steel. Tubing measurements are described with outside dimension.

Anchorage: This involves the location, style and strength of connections from the awning or canopy to the building or to its foundations.

Appliqué: Motif or design made separately, then sewn or affixed on a cloth or garment.

Awning: An architectural fabric projection that provides weather protection, identity or decoration and is wholly supported by the building to which it is attached. An awning is comprised of a lightweight frame structure over which a cover is attached.

Awning cord: Small diameter cord used for attaching awning covers to a frame or structure; most commonly a cotton, polyester or nylon with stretch resistant fiber core.

Backlit awning: (See Illuminated awning)

Basket weave: Plain weave with two or more warp and filing threads interlaced to resemble a plaited basket. Has flat look, porosity, and looseness or “give.” Can be very heavy or lightweight and made of any fiber.

Bias: Oriented at 45 degrees to the warp and fill directions.

Bolt-through: Attachment for installations mounted to a wall, or some other structure, where a bolt extends from one end of the wall or structure through the other side and securely fastened with a nut.

Braid: A narrow fabric, usually between ½”–1” wide, used as a trim. Common use is on the edge of a valance to finish the cut edge of the fabric.

Breaking strength: The measured load required to break a fabric or rope under tension; also called tensile strength.

Cadmium plating: An electro plating process which protects iron and steel. Salt spray tests indicate cadium is superior to zinc in corrosion resistance.

Calendering: A process of passing cloth between rollers (or “calendars”), usually under carefully controlled heat and pressure, to produce a variety of surface textures or effects in fabric.

Canopy: An architectural projection that provides weather protection, identity or decoration and is supported by the building to which it is attached and at the outer end by not less than one stanchion. A canopy is comprised of a lightweight frame structure over which a cover is attached.

Canvas: Cotton, linen, or synthetic in heavy weights with an even firm weave, for sails and many industrial purposes. Awning stripe canvas has printed or woven stripes.

Coated fabric: A fabric where a liquid or semi-liquid polymer has been applied in firmly adhering layers to provide certain properties. Examples of commonly used polymers are urethanes, acrylics and PVC. Many other polymers can be used to design fabrics for a specific end use.

Convex: An awning configuration characterized by a series of parallel bows in the shape of a convex curve. It produces a radius shape with flat ends.

Cordage: The general term that covers all rope, cord, lines, and string.

Count:

- Number size of a yarn.

- Number of ends and picks per inch of a weave, or their sum, as 200 count sheeting.

Crazing: This describes the condition of scratch marks on the surface of fabrics. These can occur as a result of abrasion or folding. It is usually a topical condition and does not affect the fabric’s performance except from an aesthetic point of view.

Crocking: Rubbing off of color as a result of improper dye, poor penetration, or fixation.

Cut-out lettering: Lettering or graphic elements that are cut out of a fabric and replaced from behind with letters or graphics of another material.

Delamination: This describes the separation of the individual plies in a laminate. Laminates are typically made of two or more plies that are fused together under combinations of heat, pressure and adhesive. When a lamination comes apart, delamination has occurred.

Denier: A weight-per-unit-length measure of any linear material. Officially, it is the number of unit weights of 0.05g per 450m length. It is a direct numbering system in which the lower numbers represent the finer sizes and the higher numbers the coarser sizes. In the United States, the denier system is used for numbering filament yarns (except glass), manufactured fiber staple (but not spun yarns), and tow. In most other countries, the denier system has been replaced by the tex system.

Die casting: The forming of parts by forcing molten metal into metal molds. Castings made with this process can be made to very exacting tolerance. Zinc and aluminum are most commonly used.

Di-electric welding: The terms “RF (radio frequency) welding” or “RF heat sealing” are often used interchangeably with HF (High Frequency) or di-electric heat sealing or welding. When a Di-electric material comes into contact with an electromagnetic field, some portion of the electromagnetic energy will go though a change of state and be dissipated as heat with the Di-electric. The degree to which this conversion of energy will occur is dependent on the atomic and molecular structure of the material the frequency of the electromagnetic field and the field strength.

The term Di-electric heating correctly describes this phenomenon at any frequency while RF or HF heating describes this process over the limited frequency range (1 to 200 megahertz). In the case of RF or HF welding of thermoplastics the effective mechanisms producing heat in the Di-electric are Dipolar and Interfacial polarization.

Dimensional stability: Fabrics can stretch and shrink in the warp, fill or bias directions, depending on the construction and/ or fibers employed. When a fabric is dimensionally stable, it means that stretching and shrinking have been controlled to a certain degree.

Drawing:

- The hot or cold stretching of fibers to increase orientation and reduce size.

- Process of repeated drafting of fiber slivers on a carding machine and doubling and redoubling of the slivers.

Electro galvanized or electro plated: This is similar to hot dip galvanized except the application process is different and the final appearance is smoother and brighter. Instead of dipping the metal into a hot zinc solution, the metals are charged with positive ions and put into a negative ion solution on the metal in a more uniform manner. An average plating thickness is .0002 in.

Eradication: Eradication involves eliminating with special chemicals, an existing color from a white vinyl fabric that has been pre-coated at the factory with eradicable inks.

Expansion anchors: Used to fasten awnings to concrete surfaces. They develop their essential strength by pressing hard against the side of the drilled hole in which they are set.

Extrusion coated: Dry polymers are heated and mixed through an extruder and then passed through a roller or die to flatten and spread the polymer across the width of the fabric.

Fiber: The fundamental unit that makes up a textile raw material such as cotton, wool, etc. “Fiber” is now used in the broad sense to include filament yarns, monofilaments and tow.

Fill yarn: Used to identify the weave direction transverse to the length of the woven roll of fabric. Fill yarns generally have more stretch than lengthwise yarns.

Fire proofed: A fabric or substance which has been treated so that it is absolutely impervious to flame, and will not, under any circumstances, support a flame. Erroneously used in reference to fire retardant goods.

Fire retardant finish: A finish rendering a cloth which will repel flame, or which will prevent the spreading of flame, or which will not support a flame. Usually tested for length of time it takes for a flaming portion of the cloth to extinguish itself.

Fluropolymer: This is a synthetic fiber noted for its resistance to sunlight and ulta-violet deterioration. This material will not degrade in outdoor applications for an almost unlimited period.

Fabric attachments:

- Awning molding: Usually made of aluminum, this track system has channels that accept the rope-filled hem of an awning cover.

- Lacing: This is the most traditional technique of attaching a fabric cover to an awning frame. Grommets are placed along the edge of the fabric cover. The cover is tied to the frame by lacing thin rope through the grommets.

- Screws: Fabric attachment that uses screws for fastening. The cover is stretched tightly over the frame and attached using self-tapping hexagonal screws.

- Staples: A fabric attachment that uses staples to attach the fabric to a frame system instead of screws. The fabric is stretched over a frame, then stapled to the frame.

- Staple-in-extrusions: The fabric is stapled into “slot” built into specially designed framing. The slots are then covered with strips of vinyl trim.

Hand: is the feel of a fabric to the touch.

Hand painting: A process whereby graphics are hand-painted directly on fabric.

Heat color-transfer: A graphic process that utilizes heat and a vacuum applicator to adhere color to the fabric. Any number of colors can be applied simultaneously, as pigments and resins are embedded into the fabric.

Hot dip galvanized: This refers to a finish that is the result of metal being dipped into a hot solution of zinc to add a protective, coating to the metal. Awning iron and some malleable fittings have typically been hot dip galvanized.

Hydrostat pressure: The ability of a fabric to resist water under pressure and is expressed in inches of water column.

Illuminated awning: A lighting system placed behind the fabric structure causing the fabric to be illuminated.

Jacquard weave: The type of weave to be seen in damasks, brocades, tapestries, and other complicated cloths. Made in a Jacquard loom which provides mechanisms to control the action of each warp yarn individually, if necessary.

Knitted fabric: It is different from weaving in that it uses a tying stitch to hold the other yarns together. Knitted fabrics typically stretch more than woven fabrics. Many of the substrates used in laminates are knitted because knitting is usually faster and therefore less expensive than woven fabrics.

Lacing: This is the most traditional technique of attaching a fabric cover to an awning frame. Grommets are placed along the edge of the fabric cover and then the cover is tied to the frame by lacing thin rope through the grommets.

Lag screws: Screws which are tapered to a point and do not utilize nuts. Their strength is proportional to the hardness of the wood in which they are embedded. In many awning applications that require fastening to wood framing wood lag screws may be the best available option.

Lateral arm awning (See also Retractable definition): These awnings resemble typical traditional triangular structures except they rarely have end fabric panels and they include a manual or electric cranking system that allows the awning to be rolled up or retracted against the wall.

Load: A load is anything that causes force to be exerted on a structural member.

- Dead Load: This is the self-weight of the awning or canopy frame, fabric and hardware. This load must always be included with other design loads since it is always acting on the structure.

- Wind Load: Basic wind load is a function of its wind speed. Basic wind pressure can be computed as the product of 0.00256 times the square of the wind speed (mph).

- Snow Load: A load imposed on a structure from snowfall. Snow leads vary considerably from region to region.

- Live Load: All changing loads exerted on a roof.

Mesh: Any fabric, knitted or woven, with an open texture, fine or coarse.

Mildew proof: It is unlikely that any fabric can be rendered permanently mildew proof under all conditions. “Mildew Resistant” is a more proper term. Usually refers to a treatment on a cloth with various non-toxic chemical compounds that poison or discourage the growth of mold and fungi. Effectiveness is directly proportional to the type of fungicide and the quantity of fungicide contained in the finished cloth (to the point of maximum potency). The treatment may be durable or non-durable.

Modacrylic: Generic name established by the Federal Trade Commission for “a manufactured fiber in which the fiber-forming substance is any long-chain synthetic polymer composed of less than 85% but at least 35% by weight of acrylonitrile units, except when it qualifies as rubber.”

Modulus: This is a measure that tries to explain how a fabric reacts when it tensioned and relaxed. It is used to explain things like snow and wind loads, elasticity, memory, stretch and shrinkage.

Monofilament: A single filament of manmade fiber, used as yarn.

Natural fiber: Any organic fiber such as cotton, jute, manila, sisal, etc.

Non-woven: Neither woven, knitted, nor spun. A material made of fibers in a web or mat held together by bonding agent.

Nylon: Any of a family of high strength, resilient synthetic materials, the long-chain molecule of which contains the recurring amide group CONH.

Painted cloth: Cloths which have been finished by painting in solid colors or in assorted stripes. The paint is generally applied to the surface of the cloth from fonts as the rolls of cloth pass under them. Used for awnings, outdoor furniture, umbrellas.

Plain weave: One of the three basic weaves. In plain weave, each filling yarn passes successively over and under each warp yarn with each row alternating.

Polyester: A synthetic fiber used for it’s strength and resistance to ultraviolet deterioration. It does not have the stretch and elasticity of nylon and, as a result, will often last longer.

Polymer: A synthetic material from which fibers are formed. Usually composed of large molecules (monomers) with each other.

Ponding: This involves establishing a steep enough pitch, properly spaced bows or rafters, as well as maintaining a taut fabric, so draining water or melting snow cannot cause the fabric to sag and collect water on the surface.

Pressure-sensitive graphics: Pressure-sensitive vinyl film is cut by hand or by computer to a desired design and then adhered in the proper register on the fabric as decoration.

Pre-stress: The effective long-term stress for which an awning is designed; the load in the awning that results when the fabric is pulled tight on the frame. This stress exists in the awning fabric and acts on the frame, even when the awning is not acted upon by the service loads.

RF welding or RF heat sealing: (See Di-electric welding)

Retractable awning: A movable awning that rolls or folds against a building or other structure by which it is entirely supported.

Screen printing: Similar to stencil work, except that a screen of fine silk, nylon, polyester or metal mesh is employed. Certain areas of the screen onto the fabric by a squeegee to form the pattern. Separate screens are used for each color in the pattern. More expensive than roller printing, but for limited yardage and more delicate designs, often more economical. Graphic application method capable of printing great detail and color.

Seam: A method of joining fabric panels either by welding, cementing, sewing or a combination of these methods.

Shear: A force tending to make two contacting parts slide upon each other in opposite directions parallel to their plane of contact.

Solution dyed: The process in which the color (pigment) is added to the liquid “solution” prior to fiber formation. By being added during the liquid state, the pigment becomes an integral (inherent) part of the fiber resulting in improved UV resistance.

Spray-painting or air brushing: Hand painting made sophisticated as it can achieve color blending or shading plus sharper edges by spraying inks on fabric.

Stainless steel: As the name implies, this is a special steel alloy that is made more stainless than regular steel, due to higher concentrations of chromium and nickel. Note it does not say stain proof. There are many grades of stainless steel, the more common being #304 and #316. #304 is commonly used for wire forms, and #316 for investment castings.

Staple on extrusions: The fabric is stapled into a “slot” built into specially designed framing. The slots are then covered with strips of vinyl trim.

Steel pipe: This material can be characterized as a relatively thick, round section of mild steel, with manufactured foot lengths up to 24'-0''. It is easily welded, bolted and threaded, and is adaptable to many shop environments. It is heavy and functional.

Steel tubing: Steel tubing is similar to steel pipe, but available in a range of wall thickness and shapes, including round, square and rectangular. It is easily welded or bolted, and can be obtained in higher strengths than steel pipe.

Substrate: The surface to which an awning frame is attached. A substrate also is a base fabric.

Top coating: The coating intended for the front, side or top of a fabric or membrane.

Tow: A large group of continuous filaments, such as nylon, polyester, etc., without any definite twist.

Ultimate strength: The maximum strength under which an awning material is capable of sustaining a gradual and uniformly applied load.

Uplift: Wind load on a building that causes a load in the upward direction; partial vacuum from wind loads on a building that cause a load in the outward direction.

UV resistance: Ability to retain strength and resist deterioration due to, or from exposure to sunlight.

Valance: A free-hanging projection of fabric below the main frame of an awning to create a decorative skirt; sometimes cut with scallops or sawtooth pattern to give the awning additional character.

Warp yarns: The yarns that runs lengthwise and parallel to the salvage in the machine direction of a woven or warp knitted fabric.

Waterproof: The use of the term in relation to treated cotton ducks is prohibited by the Fair Trade Practices Act “unless the product shall be impervious to the passage of any water so long as the fabric may endure.” Water resistant is the proper designation for cloths treated to resist water penetration and leakage.

Water repellent finish: A finish applied to cloth which makes it relatively impervious to the effects of water. Repellent finishes do not close the pores of a cloth.

Webbing: A sturdy fabric woven in narrow widths for use where strength is required as for seat belts, head bands, etc.

Weft yarns: The yarns that run crosswise of the warp yarns in warp knitting.

Welt: A strip of material seamed to a pocket opening as a finishing and a fabric strengthening device.

Welt Cord: A tape or covered cord sewn into a seam as a reinforcement or trimming.

Wicking: A phenomenon that occurs when moisture accumulates at the edge of a fabric where substrate yarns may be exposed, or in sewn seams where threads come in contact with the substrate and moister is absorbed into a fabric.

Wickability: The property of a fiber that allows moisture to move rapidly along the fiber surface and pass quickly through the fabric.

Working load: Working load (or working strength) is the weight in pounds that is recommended for safe working conditions. It is applied to new rope in good condition with appropriate splices and only under normal service conditions. Where dynamic loading may occur, the recommended working load should be adjusted accordingly.

Anchor Bolts: Threaded bolts used to fasten structural members to masonry. Anchor bolts can be in the form of “J” bolts or simply a threaded rod. If a threaded rod is used, there will typically be a nut and a washer secured to the imbed section of the bolt to help resist the possibilities of the bolt being pulled from the concrete.

Anisotropy: The feature of fabric wherein the physical properties and behavior are not the same in all directions.

Anticlastic: A surface with positive (Gaussian) curvature in one principal direction and negative (Gaussian) curvature in the other. A saddle shaped surface (potato chip).

Base Fabric: The uncoated fabric, also known as greige goods.

Bias: Oriented at 45-degrees to the warp and fill directions of the fabric.

Biaxial: Taken along two concurrent orthogonal directions, usually principal directions.

Boss Plate: Doughnut-shaped plate attached to a cable ear plate to reinforce the pinhole and allow a thinner plate.

Butt Seam: Seam created when the two pieces being joined are butted together and joined with a strip twice the width of the seam.

Cable Cuff: Edge treatment in which the fabric is folded over on itself to form a pocket in which a catenary cable can be installed.

Cable Fitting: Device attached to the end of a cable to allow a connection to another member. Fittings can be swaged, speltered or compression type.

Catenary: The curve theoretically formed by a perfectly flexible, uniformly dense, inextensible “cable” suspended from each of two end points. In fabric structures experience, this shape is probably not ever truly developed, but is commonly used to describe the shape developed at the boundary of a uniformly stressed fabric structure attached to a cable which is restrained only at its end points.

Catenary Cable: Steel cables that run through the pockets on the perimeter of a tension structure fabric. The shape of the cable follows that of the pocket, which is typically curved with a ratio of 1:10. The length of the cable is to be determined from by the engineer supplying the fabric patterning. The thickness of the cable is to be determined by the engineer who is calculating the reaction loads at the cable ends.

Catenary Edge: Method of securing the edge of a panel with a cable tensioned between two fixed points.

Catenary Pocket (AKA “Banana Pocket”): This is the pocket that is placed at the perimeter of the fabric cover to secure the catenary cable. The pocket has a curve with a ratio that is defined by the fabric patterning, but is typically close to a 1:10 ratio. This means for every 10 feet of length, there will be about a foot of bend to it. Due to the curvature of the shape, the pocket is typically fabricated by sealing together two halves of the pocket together with an overlap of 1” to 2” at the outside edge of the pocket.

Clevis: Device used with a cable stud end or a threaded rod to form a pinned connection that is somewhat adjustable.

Coating: A material applied to a fabric for waterproofing and protection of the fabric yarns.

Coating Adhesion: Strength of the bond between the substrate of a fabric and the coating.

Compensation: The operation of shop fabricating a fabric structure or pieces of the structure smaller in the unstressed condition than the actual installed size, to account for the stretch at pre-stress level.

Crimp: The extent of deformation normal to the plane of the fabric that the fill and warp yarns undergo as they are woven together.

Detension: Relieve the tension or stress in a membrane.

Elongation: The change in lengths of a material sample; normally this is associated with some load or force acting on the sample. In fabric, this elongation does not normally refer to true strain of the fiber elements as in the classical sense; but, rather, normally refers to the “apparent” strain resulting from a straightening out of the crimped yarns in the fabric matrix.

Equilibrium Shape: The configuration that a tensioned fabric surface assumes when boundary conditions, pre-stress level, and pre-stress distribution are defined.

Fabric: A woven or laid cloth made of yarns.

Fabric Clamp: Device for clamping the edge of a fabric panel, usually a bar or channel shape and made of aluminum or steel.

Fiber: The basic thread of the material from which the yarns and fabrics are made.

Fill Yarns: The shorter yarns of a fabric, which usually run at right angles to the warp yarns. Also known as weft yarns.

Flutter: Excessive, uncontrolled movement, usually caused by the interaction between the structure and wind. This occurs when the fabric lacks sufficient pre-stress.

Footing: The large concrete anchoring structure that holds the tension structure securely to the ground. The top of the footing is typically flush with the ground level. The footing is comprised of a matrix of steel rebar that is referred to as a cage. The concrete is poured into the hole in the ground that holds the cage. The anchor bolts get placed into the top of the footing at their precise location as indicated in the shop drawings. A certified engineer must calculate the size of the footings. The size of the footing must contain enough weight to hold down the tension structure for the wind loads in the area.

Form Finding (AKA "Form Generation"): The process of determining the equilibrium shape of a fabric structure.

Greige Goods: Uncoated fabric. Also known as the base fabric.

Guy Cable: This steel cable is used to support the structural integrity of the steel frame. It may be attached at the ends of the steel struts (or “arms”) to hold them together and resist them from movement relative to each other. Unlike catenary cables, the lengths are calculated by a straight point-to-point dimension. The engineer will need to determine the thickness by calculating the maximum stress on the cable.

HDPE: High Density Polyethylene (HDPE) fabric is an extra heavy duty woven mesh fabric that blocks up to 95% of harmful UV rays. This superior Fire Rated Knitted shade fabric is designed for use in modular shade structures and shade sails.

Hysteresis: The failure of fabric to return to its original geometry after the strain-inducing force has been removed.

Keder: Brand name for the solid PVC cord used at a “rope edge”. Rope edges provide strength and a surface to evenly distribute fabric tension forces.

Lap Seam: Seam created when the two pieces being joined are overlapped by the width of the seam.

Light Transmission: A measure of the portion of light striking a fabric surface that passes through the fabric and into the space to provide daylighting.

Mast: The principal upright in a tension structure.

Membrane: The fabric panels used in tension structures.

Membrane Plate: Metal plates attached to the membrane corners used for securing the membrane to the frame.

Modulus of Elasticity: The ratio of the change in stress to the change in strain. Usually defined as a force per unit width of a membrane material.

Node Points: Intersection points of the elements used to define the fabric shape in the structural analysis; these are normally given in terms of a three-dimensional coordinate system.

Patterning: The process of defining two-dimensional pieces of fabric, which can be spiced together to form a desired three-dimensional shape. M-Panel is an add on tool for AutoCAD that has the ability to assist in the process of patterning.

Poisson’s Ratio: The ratio of lateral strain to longitudinal strain; may take a wide range of values due to the deformation characteristics of a woven material.

pre-stress: The stress state that exists in a fabric structure when it is not acted upon by service loads; usually induced by the boundary conditions of the fabric membrane.

PTFE: “Polytetrafluoroethylene”, commonly known by its trademark name Teflon™. This coating is applied to a fiberglass scrim to produce a high strength tension structure fabric membrane with a life expectancy of thirty plus years. PTFE may also be expanded and woven into a fabric that can be coated with a fluoropolymer to create a high strength architectural fabric.

PVC: “Polyvinyl chloride”, properly mixed with plasticizers for flexibility and applied to a polyester scrim makes for a high strength and popular tension structure fabric membrane. The life expectancy and cost are proportionally lower than PTFE.

Radius of Curvature: The inverse of the magnitude of (Gaussian) curvature at a location on a membrane surface. The magnitude is typically considered in two principal directions. The orientation of the principal directions and their magnitude may vary continuously over the surface.

Rebar Cage: A reinforcing matrix of steel rods used to strengthen concrete.

Reinforcement: An additional layer of fabric placed in an area of high stress to protect the main fabric.

Roll Goods: Edge treatment in which the edge of the fabric is folded over on itself and a rope or cord is incorporated in the fold to increase the strength of the clamped fabric.

Sectionalizing: Method of field joining large fabric panels utilizing clamping hardware.

Sleeve: A tube of fabric, which loosely contains a structural element such as a cable, rod, etc.

Spelter: Type of cable fitting in which the strands of the cable are opened inside the fitting and molten lead is poured into the fitting to secure the cable.

Stay Cable: A steel cable that is used to stabilize the mast in response to the forces created by wind loads. The stay cables are used to resist movement of the structure relative to the earth. One end of the cable will typically connect to the end of the steel frame near the fabric connection. The other end will terminate to a sturdy section of the mast or a footing in the ground.

Swage: Type of cable fitting in which a sleeve fits over the outside of the cable and the sleeve is compressed around the cable to form a tight fit.

Synclastic: A surface with positive (Gaussian) curvature in both principal directions. A bubble shaped surface.

Thimble: Device used in a simple cable loop end to secure the cable and bear against the pin. Thimbles are usually used with shackles.

Top Finish (AKA "Topping"): An additional coating sometimes used on fabric for greater protection against UV degradation or for ease of cleaning purposes (i.e. Ferrari’s PVDF named “T2®”; or Dupont’s PVF named “Tedlar®”).

Turnbuckle: Threaded device used with cables or rods to allow adjustment.

Ultraviolet (UV) Degradation: The deterioration of a fabric under long-term exposure to sunlight. Using a top finish on the fabric will help prevent the UV degradation.

Uniaxial: Taken along one direction, usually a principal direction.

Warp Yarn: The long straight yarns in the long direction of a piece of fabric.

Weaving: The process of making a fabric from yarns passing alternately over and under each other.

Weft Yarn: The shorter yarns of a fabric, which usually run at right angles to the warp yarns. Also called the fill yarns.

Weldment: Connection component, usually steel, for the attachment of cables and/or fabric. If may be free-floating or connected to other membranes.

Wicking: The conveying of liquid by capillary action along and through the yarns of the base fabric.

Wire Rope Clip: U-shaped bolt with a special insert, specifically designed to clamp a wire rope to itself when forming a loop end for temporary cables.

Wrinkles: Furrows or ridges on the normally smooth surface of a fabric structure, which are indicative of extreme differences between the principal stresses typically resulting from a lower stress perpendicular to the furrow.

Yarn: A number of fibers grouped together to make a thicker strand for weaving. They may be twisted together or parallel to each other.